The future of climate-resilient construction

How ZS2 and SEKO helped preserve critical infrastructure from devastating wildfires.

The images of the Tataskweyak Transition Centre still standing after wildfire tore through Split Lake were dramatic on their own. But the real story begins once the smoke cleared — in understanding why this building performed differently than so many others in fire-prone regions.

The answer lies in choices made long before flames appeared on the horizon. Prefabricated panel assemblies closed the building faster and reduced exposure points. Magnesium cement sheathing resisted ignition, held its strength under extreme heat, and released steam instead of toxic smoke, helping safeguard structures and air quality during fire events. Together, these details turned a vulnerable construction site into a resilient community facility.

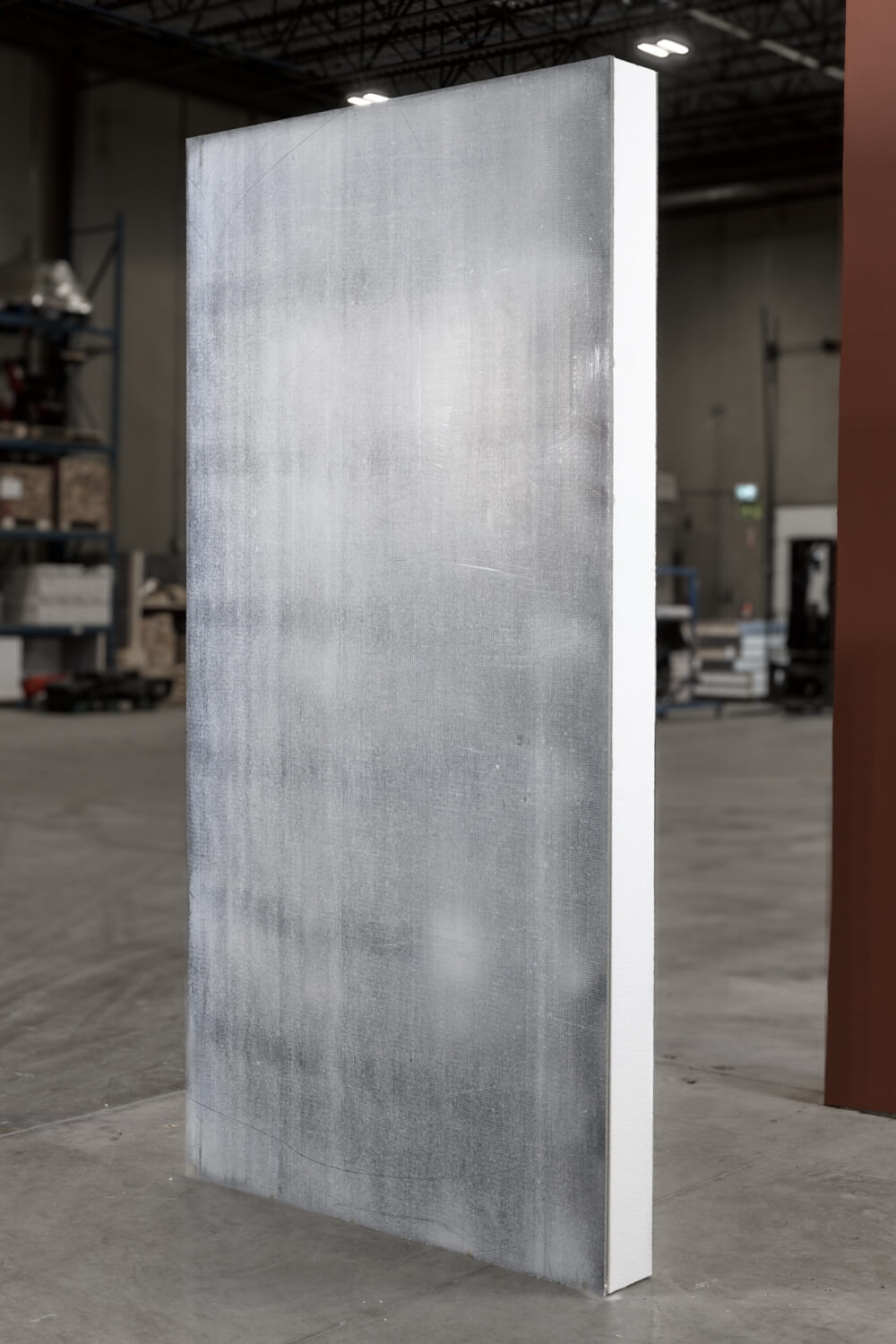

ZS2 Technologies flagship product is TechPanel® — a Canadian-manufactured system that combines framing, insulation, and a highly fire-resistant magnesium cement sheathing. Unlike conventional stick framing or poured concrete, TechPanel® arrive manufactured to spec, with openings pre-cut for windows, doors, and mechanical systems. Crews can take a project from foundation to full enclosure in less time, with fewer people and less waste than traditional methods. The system combines the benefits of material science with the performance of prefabrication — delivering a continuous envelope that resists mold, water, fire, and pests while providing exceptional thermal performance in the harshest climates.

At the core of that performance is magnesium cement technology. “As an element, magnesium oxide is one of the most stable elements at high heat known to man,” said Scott Jenkins, ZS2 CEO. “It doesn’t just avoid ignition; it doesn’t add fuel to the fire. What mattered in Split Lake was pairing that science with a tight, fast, panelized assembly.”

The 9,766 sq. ft. Transition Centre was built with a full TechPanel® envelope — roof, walls, and floors. SEKO Construction, a design-build firm trusted across northern and Indigenous communities, led the full execution of the Transition Centre. From the foundation to the installation of the TechPanel® roof, walls, and floors, the team ensured the detailing and finish required for long-term performance. The result was a facility enclosed quickly, with precise connections and no gaps. The footage speaks for itself — when wildfire swept through Split Lake, the facility stood virtually unscathed.

“In northern remote communities, fire and mold resiliency are huge issues,” said SEKO Vice President Peter Shoulak. “ZS2’s system ticks those boxes, and when products perform, it’s easy for us to direct our design team to use them.”

In an upcoming webinar on Sept. 18,ZS2 will detail the project from both the material innovation side and the builder execution side.

“You’ll get a chance to ask some thought provoking questions about how we are currently building and how we should be building and how that can be integrated with other technologies, whether it’s residential, commercial, industrial.” said Jenkins. “We didn’t create cold fusion. We made a better cement, and that cement makes better building materials”

“When we find partners that are good partners, when we find products that are good products, it’s easy for us to dictate to our design team that they use those products,” said Shoulak.

SEKO and ZS2 have gone on to partner on numerous projects, including a daycare building for the Yellow Quill First Nation, a hockey arena at the Cote First Nation and the Blue Sky Healing Centre at the Pine Creek First Nation.

Construction at Split Lake meant navigating extremes — from installing panels in –30°C winter conditions to withstanding wildfire heat months later. While the wildfire case is extreme and dramatic, the more mundane benefits are equally impressive.Offsite manufacturing made the system rapid and deployable in a remote setting.

Through collaboration, ZS2 provided the resilient shell and SEKO delivered the execution — together ensuring faster builds, fewer delays, and predictable logistics in a challenging environment. Energy performance was just as critical. Lytton, B.C. tragically was devastated by wildfire flames but few know about the region’s ongoing energy crisis.

“The year after B.C. had its hottest summer on record it had its coldest winter on record,” said Jenkins. “Community members had $1,000 energy bills to heat their homes.”

ZS2’s rigid insulation dramatically brings these costs down while also increasing disaster performance.

Jenkins also foresees that ongoing extreme weather events are already creating a challenge for insurance companies that climate resilient technology can address. Insurance providers in North America are already pulling out of disaster-prone regions.

“The industry is going to be forced to change because people won’t live in a home that can’t be insured,” said Jenkins. “It will be a massive paradigm shift.”

The facility’s survival came down to details: fire resistant sheathing, tight panel connections with no gaps, and a gravel lot line that slowed the spread of flames. Together, those choices added up to resilience. The bigger picture is clear. This wasn’t luck — it was the result of specifying the right materials and systems from the start. If it can work in a remote northern community facing climate swings and wildfire threats, it can work anywhere.

Cities and communities are demanding high-performance solutions that are faster, safer, and stronger — and the right builders with the right materials can deliver them.

He and Shoulak encouraged builders and owners to attend the webinar to get a deep dive into the technology that saved the Tataskweyak Transition Centre, the lessons learned, and what this project means for the future of climate-resilient construction.