Plantd creates building materials from perennial grass

The U.S. company has a new method for sustainable construction products and wants them to be an industry standard.

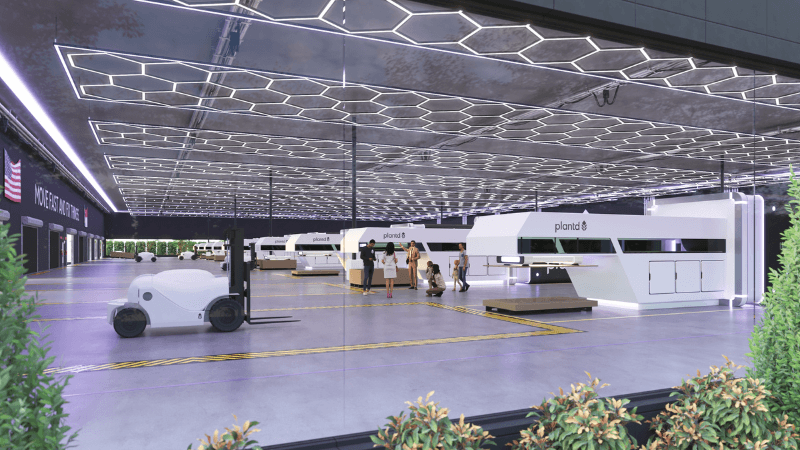

Plantd’s vision for manufacturing sustainable building products. – Plantd

Key Takeaways:

- Plantd creates carbon-negative building products out of fast-growing grass.

- Plantd plans to establish their agriculture supply chain and build a modular automated continuous press for engineered building materials.

- They are currently working with U.S. builders and architects to integrate their materials into projects.

The Whole Story:

There’s a new player in the sustainable building materials market.

Plantd out of North Carolina has announced its $10 million Series A funding round. Led by American Family Ventures, the funding supports Plantd’s work on carbon-negative building materials.

“We are thrilled to back this exceptional and visionary team,” said Kyle Beatty, managing director at American Family Ventures. “Plantd is creating fundamentally better construction materials that are cost-effective and truly carbon negative. We have been impressed by how they have reinvented every step of the production process from first principles, all the way from input material to logistics.”

Plantd’s production team is led by co-founders and engineers Huade Tan and Nathan Silvernail, who worked together for years at SpaceX designing and building key systems and components of the Dragon cargo and crew spacecraft. Together with co-founder and CEO Josh Dorfman, Plantd is is looking to redefine the value chain for engineered building materials.

Plantd’s proprietary low carbon-emissions production technology uses fast-growing perennial grass to create durable, carbon-negative building materials. The company says its products can outperform competitive products on key attributes, including strength and moisture resistance.

Starting with structural panel products for walls and roofs, Plantd will fabricate building materials that are a direct substitute for traditional home construction products and require no alternative installation techniques.

The company explained that by cultivating fast-growing perennial grass instead of cutting down trees and pioneering novel production technology to minimize carbon emissions, Plantd’s structural panels retain 80 per cent of the atmospheric carbon dioxide captured in the field, which is then locked away inside the walls and roofs of new homes.

“We can’t move quickly enough to solve climate change unless we develop profitable methods to take carbon dioxide out of the atmosphere,” said Dorfman. “We’re going to change an industry by offering builders a better product at the same price and, in the process, scale a business that can help save the planet.”

Plantd plans to use this round of funding to establish their agriculture supply chain and build the first-of-its-kind, modular automated continuous press for engineered building materials. The company says it is currently working with the nation’s largest builders and architects to integrate these materials into their projects and quickly make them a standard in the industry.

Plantd officials stated that their ultimate vision is to build the factory of the future, ensuring that new homes and buildings contribute to reversing the effects of climate change.