Is Build Canada Homes modular construction’s big moment?

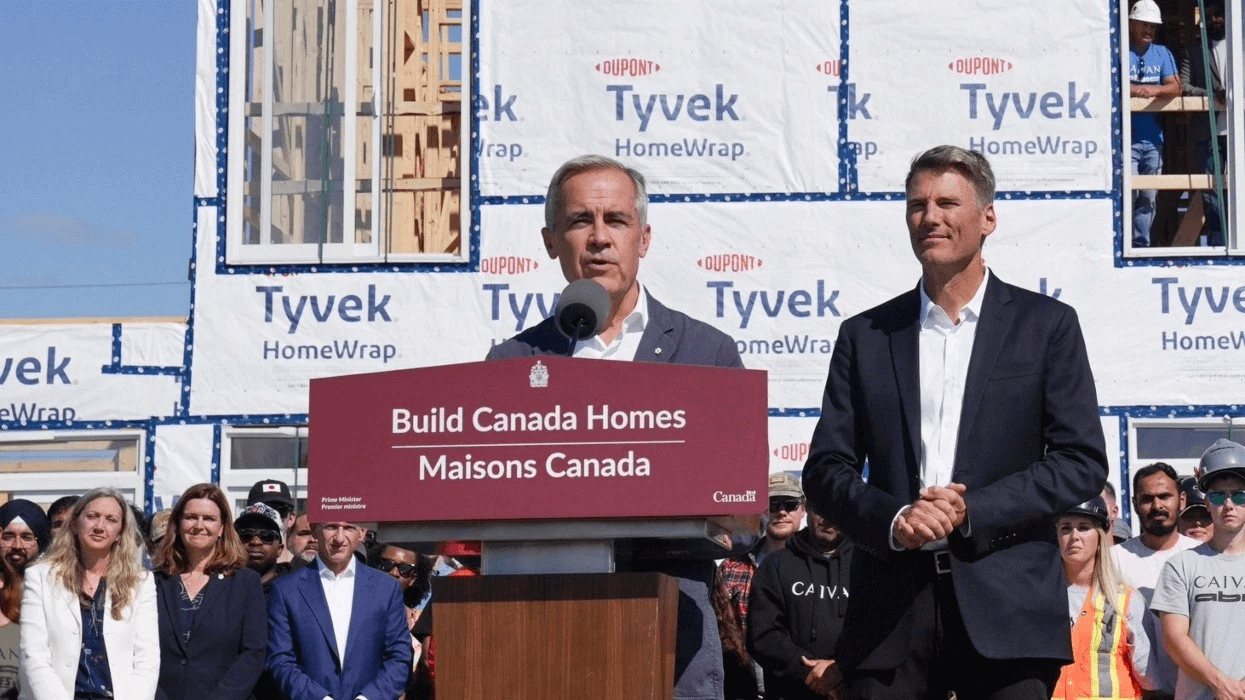

Prime Minister Mark Carney aims to use construction technology to unlock thousands of new units.

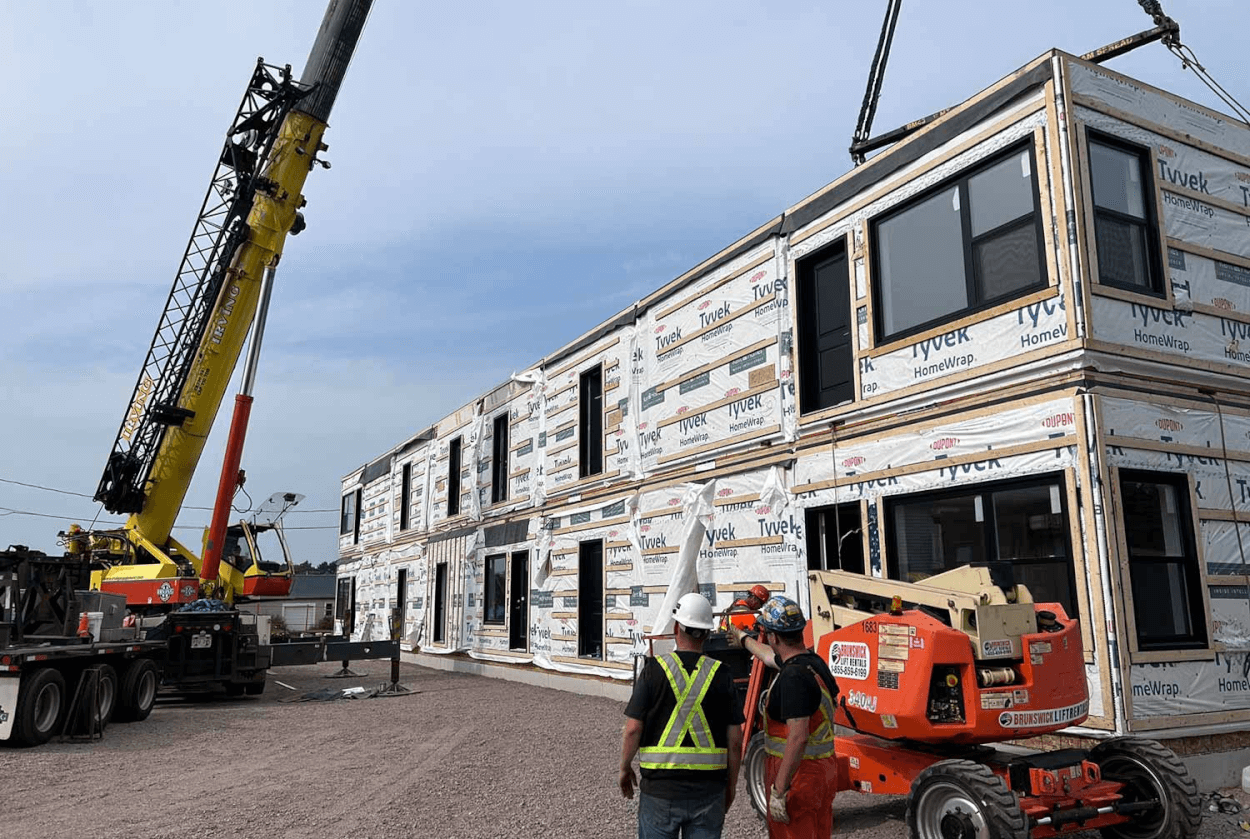

2026 and beyond is shaping up to be historic for the modular and industrialized construction movement.

As Canada embarks on a new strategy to tackle one its greatest modern challenges, affordable housing, the federal government is looking to industrialize the construction process as a way to bring building costs down.

Build Canada Homes is Canada’s new federal agency tasked with tackling the housing crisis by building affordable homes at scale, financing projects, and supporting innovative building methods. It will work with provinces, municipalities, territories, and Indigenous communities to expand transitional, supportive, and community housing. Its focus is on non-market, mission-driven housing—delivered by non-profits, co-ops, Indigenous housing providers, and organizations serving vulnerable populations.

“For the deeply affordable homes that we finance and build, Build Canada Homes will catalyze bulk orders of offsite construction of prefabricated and modular homes, specifying the use of Canadian technologies and resources,” said Carney.

For entrepreneurs like Troy Ferguson, Founder and CEO of 720 Modular, it could mean a new landscape of opportunity.

“I think this is really going to be the spark that gets the pistons moving. I think it will allow for more investments, fill up the tank and attract more people into the space so we can really achieve the benefits of modular,” said Ferguson.

He explained that one of the biggest factors holding the industry back is demand.

“Give us demand, give us stability, that will drive opportunity which inevitably attracts investment,” he said.

And that’s not just about money. It could also attract new workers to the industry.

“AI won’t fix a hole in your room or build you a roof, and this is a great way to attract people who don’t want to be in the wet and cold, they want consistent hours,” said Ferguson. “They want to go to work, do a good job and go home. We can really leverage the knowledge of people in the sector who are thinking of retiring. Let’s get them in factories to lead and teach. That’s how we’re going to build an industry.”

Rhys Kane, Director of Business Development at ROC Modular, agreed saying that the government’s new direction could be an industry-making moment. He explained that construction is the last big sector of the economy to modernize and truly industrialize.

“Every other industry has embraced technology, automation and mass industrialization. Construction is ripe for that,” he said.

It’s the same dynamic that that’s been seen in countless examples of consumer technology. Two decades ago, flat-screen TVs were luxury items that were out of reach for most households. But as demand grew and production scaled, prices plummeted. Advocates say modular housing is poised for a similar shift: once factories run at full capacity, costs can fall dramatically, unlocking real affordability.

Modular builders say the issue has been getting enough consistent work and product-based commitments. Kane Believes the Build Canada Homes effort could change that and Canada’s modular industry is well-established and ready to respond. The factories exist, experienced builders exist and capacity is waiting. He noted that Canada, unlike other countries, is particularly suited for modular work.

“It’s such a big country, it’s so spread out that there’s so many remote and rural locations that have these access to trade difficulties. In some countries it doesn’t make as much sense, but in Canada it really does,” said Kane.

With large commitments and an emphasis on construction technology, Kane believes there could be a new wave of companies entering the modular space. But he stressed that they should be wary, as it is more complex than it seems.

“This isn’t an easy industry to be in,” he said. “There’s a lot of moving parts. We’re a product supplier and a modular manufacturer, but we aren’t just supplying a fridge or a window. There’s an entire building component with lots of moving parts related to relationships with general contractors and design teams.”

Antonio Manchisi, Vice President of Construction, Sapphire Balconies, explained that the Build Canada Homes initiative is likely to push Canadian architecture toward more standardized, modular, and productized design, where efficiency, repeatability, and speed take priority. Architects will be pushed to adopt Design for Manufacturing and Assembly (DfMA) principles, integrating modular systems, mass timber, and low-carbon materials sourced domestically.

“While this shift favours functional, cost-conscious housing, it also creates space for innovation in community-focused amenities, digital design tools, and adaptable templates that can balance national housing needs with regional identity,” said Manchisi. “In effect, BCH could redefine Canadian architectural trends by blending industrialized construction with sustainability and local character.”

But unlocking the benefits of modular is about more than consistent demand and technology. It’s about managing risk and costs.

Beyond the nuts and bolts of building, Atul Bhatt sees Build Canada Homes as an opportunity to improve the business model of modular construction so it can reach its true potential. During a decade-long stint at CMHC, Bhatt had spent years looking for innovative ways to make housing affordable.

“I came to the realization that the way we build now and pay later is the core culprit,” He said. “Housing costs have to keep going up to keep capital markets stable. But now ‘build now pay later’ economics are not working because house prices have gone so far ahead of the wages that pay later is not probable. It’s not going to happen. It’s not plausible.”

If housing prices don’t go up, investments dry up and prices go down. If prices go down, trillions in mortgages and mortgaged-backed securities go down. Bhatt says this risk of market destabilization means prices have to be held to a certain minimum level, but how do you bring that level down? The answer is to bring the construction costs down so that developers will be incentivized to not increase the housing prices so aggressively. But with input costs rising 30-40% since 2021, building cheaper is a tall order.

“Mr. Carney is absolutely right in saying industrialized construction is the only way out. The U.S., Germany, Japan and everybody is now on that same bandwagon,” he said.

Bhatt argued that it’s about aligning the construction financing and insurance model with the factory-built process. His analysis found that industrialization is a great idea, but fraught with risks that threaten to derail it.

“I dug deep into 60 to 70 years of history of industrial construction across the US, Canada and the UK and I came up with a whole lot of failure stories that told me what went wrong,” he said.

In all, his research identified a list of 217 risks for modular construction. The biggest ones cluster into a few clear buckets:

- Turning construction from a project-by-project model into a continuous factory business (which needs a reliable order pipeline, trained staff and compatible design/technology);

- Design and engineering incompatibility (small site tolerances compound when stacked in factory-built units);

- Supply-chain and logistics limits (material availability and shipping constraints)

- Finance/insurance challenges (factories require far more up-front capital and lenders lack standardized valuation/quantity-survey processes, forcing developers to commit much more equity). Underlying all of this are land-use, zoning, permitting and site-topography issues plus the coordination questions about who assesses site suitability and who bears those costs.

“There are so many failure points hidden in construction in general and insurance masks many of them,” said Bhatt. “The frequency of problems in modular is not higher than site build. Modular is not a worse method. It’s a better method. But the awareness of risk management in planning and coordination is very low.”

To address this, he is in the process of converting into a digital risk management platform for the modular construction sector. Proponents and projects could have a credit rating-like modular risk score and even receive tips on how to mitigate risks that are identified.

“That’s the most solid basis of underwriting that you can ever find in the construction industry,” said Bhatt.

He plans to launch ModuRisk later this year with a focus on building an industry risk intelligence platform that will take modular construction from a relatively smaller, niche industry to a predictably larger, industrialized method of construction, through smart management of risks.

But he believes the government has a part to play as well. To support Build Canada Homes and the modular sector, he suggests they move beyond just funding projects and instead structure a true public-private partnership around three pillars:

- Create a 10-year rolling demand forecast for housing needs in each province and municipality, based on existing urban master plans (housing, economic, climate, and transportation)

- Align permitting and zoning flows with those forecasts, ensuring municipalities that allocate land for housing receive funding

- Support factory development by establishing a factory performance guarantee fund that helps de-risk investment, enabling lenders and insurers to participate with confidence.

He believes that together, these measures would provide clear demand signals, coordinated land use, and reduced financial risk.

“That is a recipe for building at scale,” said Bhatt.