Finding a cure: 8 leaders in green concrete technology

These companies have the potential to eliminate a massive amount of CO₂ from the construction process.

The construction sector is a major contributor to global carbon emissions, with concrete at the forefront of the challenge. As one of the most widely used building materials in the world, concrete production accounts for roughly 8% of global CO₂ emissions, largely due to the energy-intensive process of making cement, its key ingredient.

This environmental toll poses a critical challenge as urbanization and infrastructure demands continue to grow. However, a new wave of sustainable concrete companies is emerging, offering innovative solutions to reduce emissions, recycle materials, and incorporate alternative, eco-friendly methods of production, paving the way for greener construction practices.

CarbonCure Technologies

Nova Scotia-based CarbonCure has pioneered a technology that injects recycled CO₂ into fresh concrete, where it mineralizes and becomes permanently embedded, reducing the carbon footprint of concrete. As of October 2024, CarbonCure and its global network of concrete producers have saved 500,000 metric tons of CO₂ across 7.5 million truckloads of green concrete.

CarbiCrete

Quebec-based CarbiCrete has developed a cement-free concrete that sequesters CO₂ during production, resulting in a carbon-negative product. First developed at McGill University, their tech enables the production of cement-free concrete. The process uses an industrial by-product – the slag from steel factories – to replace cement as a binding ingredient in concrete products. The process injects CO2 into the fresh concrete to provide strength, while permanently sequestering CO2 within the resulting products. In December 2024, CarbiCrete collaborated with Aecon and Lafarge Canada to construct a low-carbon building in Ontario, utilizing their cement-free concrete masonry units.

Lafarge Canada

Lafarge has developed its own solution to reducing the environmental impact of concrete. ECOpact offers up to 90% lower CO₂ emissions compared to standard (CEM I) concrete with no compromise in performance. It contains an innovative mix of supplementary cementitious materials and admixtures technology. Where norms allow, ECOPact can include construction and demolition waste. In November 2024, Lafarge Canada and The Daniels Corporation announced a collaboration on the Daniels on Parliament project in Toronto, achieving up to a 25% reduction in embodied carbon through the use of ECOpact.

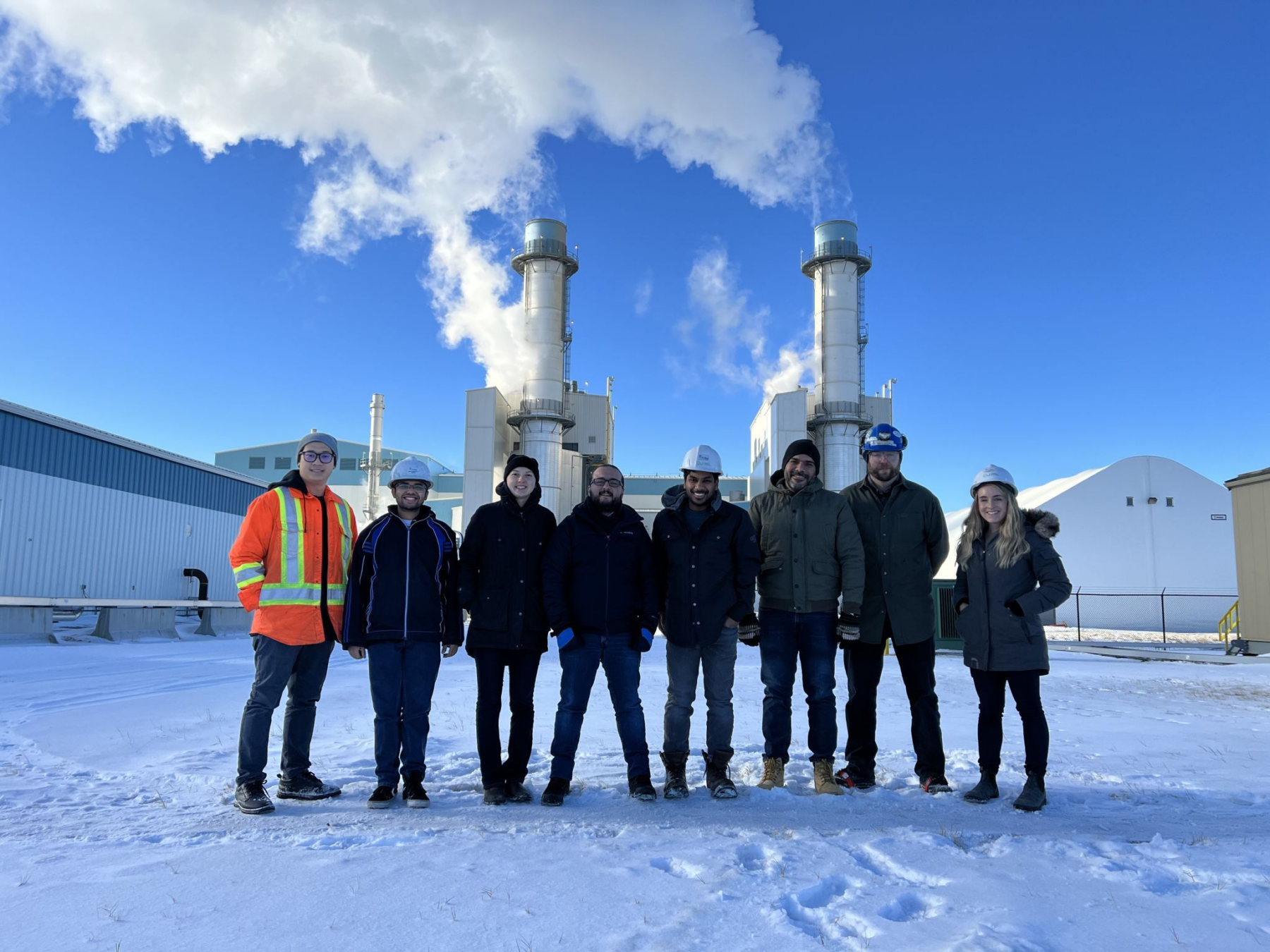

Carbon Upcycling

Alberta-based Carbon Upcycling captures byproducts from industrial sources and then transforms them into high-performance additives for concrete, enhancing its strength and durability while reducing its carbon footprint. Their patented technology combines CO2 with waste materials like fly ash and steel slag, permanently mineralizing the carbon and creating high-performance additives for concrete. This process can reduce the clinker content in cement by up to 50%. Their team recently wrapped up a three-year pilot study with the Minnesota Department of Transportation, showing that low-carbon concrete is 30% stronger than existing roadways.

Ecocem

Ecocem produces low-carbon cement by replacing a portion of clinker with slag, a byproduct of steel production. This innovative approach reduces greenhouse gas emissions while maintaining strength and durability. Ecocem’s efforts are part of a broader movement to decarbonize the cement industry, with the company aiming to revolutionize the industry by decarbonizing this highly polluting sector.

CEMEX

A global building materials company, CEMEX offers sustainable concrete solutions, including their low-CO2 Vertua concrete products. Vertua concrete uses innovative geopolymer cement solutions and sustainable raw materials to achieve lower carbon footprints. These concrete mixes can achieve up to 70% reduction. Their Vertua Ultra Zero mix is a carbon-neutral product, offsetting remaining unavoidable emissions through partnerships with carbon offset specialists. Founded in 1906 and headquartered in San Pedro, Mexico, they are a global leader in the building materials industry, operating in over 50 countries.

Sublime Systems

Sublime Systems, founded in 2020 by Dr. Leah Ellis and Prof. Yet-Ming Chiang at MIT, is a groundbreaking startup revolutionizing cement production through electrochemistry. Their innovative process dramatically reduces carbon emissions by using renewable electricity to produce cement at room temperature, eliminating the need for fossil fuel-powered kilns. In a major recent development, Holcim invested in Sublime Systems in September 2024 to help scale up their first commercial manufacturing facility in Massachusetts, giving Holcim a large share of Sublime Cement production.

Carboclave

Carboclave is an Ontario-based company founded in 2016 that specializes in innovative concrete manufacturing technologies aimed at reducing carbon emissions. The company employs a unique curing method that utilizes carbon dioxide (CO2) instead of traditional steam, resulting in prefabricated concrete products that are not only stronger and more durable but also have a significantly lower carbon footprint—up to 50% reduction in embodied carbon. Carboclave’s technology enhances the curing process through exothermic mineralization, which not only accelerates production but also contributes to sustainability by transforming concrete manufacturers into carbon sinks.