PHOTOS: 6 iconic Canadian structures being built

Bridges, highways, towers – take a look at what Canada’s historic projects looked like before they were completed.

Canadian Parliament building

A devastating fire couldn’t crush the spirit of early Canadians. After a fire swept through the Centre Block’s House of Commons reading room, only the building’s exterior walls and the Library of Parliament Survived. Architects John A. Pearson and Jean-Omer Marchand were soon chosen to lead the redesign. The Centre Block was reimagined with much of its original look but with modern materials and an improved layout. The original plan was to start again on the original Centre Block site, but more space was needed so the remains of the original walls and the rubble foundation were demolished and rebuilt with load-bearing concrete walls and a steel frame.

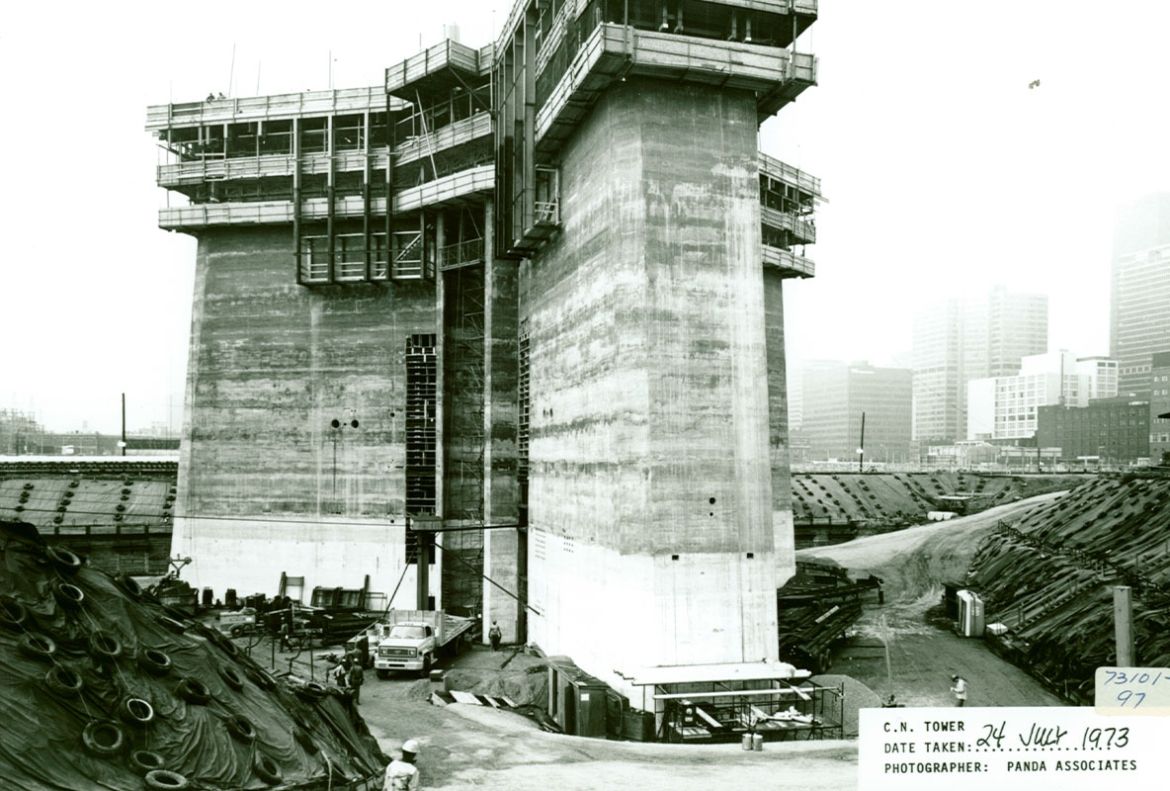

CN Tower

Long before Drake sat atop Toronto’s iconic tower for his album “Views” the tower was built by more than 1,500 workers over 40 months. It was envisioned by Canadian National, a crown corporation responsible for the nation’s largest railway network. According to the Canada Lands Company, the crown corporation that currently owns the tower, Canada National wanted to demonstrate the aspirations of Canadian innovation and industry. To achieve the tower’s tapered contour, construction crews poured concrete into a massive mold known as a slipform. As the concrete hardened, the slipform, supported by a ring of climbing jacks powered by hydraulic pressure, moved upwards, gradually decreasing in size to create the structure’s curve. The tower was topped off in 1975 at 553 metres.

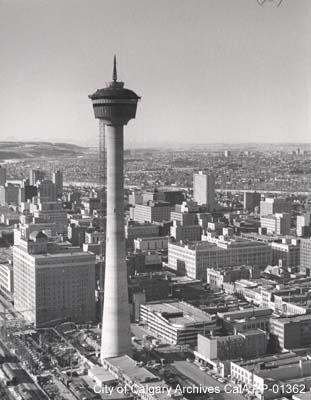

Calgary Tower

Reaching 191 metres above Calgary’s downtown core, the Calgary Tower gives visitors one of the best views in Alberta. The Husky Tower, the tower’s original name, was built as a joint venture between Marathon Realty and Husky Oil to honour Canada’s centennial and promote the downtown core as a part of a Calgary urban renewal program. The concrete and steel tower was designed by architect W.G. Milne and built by Poole Construction Co., which is known today as PCL Construction. The techniques used were innovative for the time. Crews conducted a continual pour of concrete using a relatively new slip-forming construction technique. Pouring began May 15, 1967 and was completed 24 days later. The record pour in one 24-hour period was 39 feet. It was also the first structure in the Western provinces designed to withstand earthquakes.

Lions Gate Bridge

This iconic structure connects the north shore to downtown Vancouver opened in 1938. In this shot, three workers operate a compressed-air-driven rotary machine to wrap cables during the last month of construction. According to the Museum of North Vancouver, workers were not issued any special clothing, footwear or safety equipment. The bridge was financed by the Guinness brewing family to create access to its British Properties lands in West Vancouver. Ownership was transferred to the province in 1955. Tolls were removed in 1963 and the bridge underwent a major restoration in 1998.

Trans-Canada Highway

You’d be hard-pressed to find a Canadian who hasn’t driven along some stretch of the Trans-Canada Highway – Canada’s longest national road. The route extends east-west across Canada between Victoria, B.C. and St. John’s, Nfld. It cuts through all ten Canadian provinces and links the country’s major cities. The highway’s completion was officially celebrated in 1962 when the final stretch was completed through Rogers Pass in B.C. According to Parks Canada, A.D. Booth, a truck driver from Salmon Arm B.C., was one of the first to drive the section when he transported 264 crates of sun-sweet strawberries to Calgary fruit buyers. Before the highway was complete, goods like strawberries took three days to travel by rail. Crews blasted, bridged and paved 7,821 km of highway to build this iconic piece of infrastructure.

Habitat 67

This iconic Quebec structure is located in the Cité-du-Havre, a century-old artificial peninsula enlarged for Expo 67. According to Safdie Archtiects, the project’s designer, the housing project showcased early pre-fabrication techniques. Crews built 365 construction modules that connected to form 158 residences. The units are connected to each other by post-tensioning, high-tension rods, cables, and welding, all of which combine to form a continuous suspension system. The interior components were produced, assembled and installed into each box unit in the factory, with single-unit bathrooms of gel-coated fibreglass, kitchens manufactured by Frigidaire, and window frames made of Geon plastic.