12 innovators advancing construction safety

From brainy boots to wireless alarms – these companies are in search of smarter safety solutions.

SmartCap creates wearable tech that prevents you from getting drowsy on the job. – SmartCap

One hundred and ninety three.

According to the Association of Workers’ Compensation Boards of Canada, that’s how many construction workers died on the job in 2020.

Everybody should go to work and come home safe. It’s that simple.

As construction projects and sites have grown more vast and complex, companies and organizations have sought to keep up by creating new ways to ensure workers are kept safe. Below are some of their stories.

1. Kenzen

What if you could know when your workers are overheating or need to take a break? Kenzen is making this data a reality. It provides heat and safety monitoring of key physiological indicators for each worker, such as core body temperature, heart rate, and exertion levels. The Kansas City-based company’s approach has caught the attention of the U.S. Department of Homeland Security (DHS) which recently awarded them $161,000 in funding.

2. Ramtech

Ramtech Electronics has been supplying wireless solutions since 1990 from its Nottingham headquarters. They soon saw that their technology could apply to the jobsite and began developing wireless temporary fire alarms for construction. They also created the REACT system which gives construction teams a simple and secure means of communicating fire, medical and other site emergencies to affected personnel, both on and off site. Their team recently published a white paper exploring the modern fire and life safety solutions for construction in North America.

3. Hexoskin

It’s not quite Ironman’s suit, but it still could help keep you safe. Hexoskin Smart Garments include textile sensors embedded into garments for precise and continuous cardiac, respiratory, and activity monitoring. The Montreal company’s users can visualize, report, and analyze their data with the Hexoskin Connected Health Platform. In Australia, the technology is being used to monitor the health and vitals of truck drivers to study the impacts of driver fatigue.

4. Blackline Safety

It’s all about the internet of things (IoT) with Blackline Safety. The Calgary company says its connected safety devices and predictive analytics helps companies drive towards zero safety incidents and improved operational performance. Blackline provides wearable devices, personal and area gas monitoring, cloud-connected software and data analytics for companies in more than 100 countries. Blackline Safety recently closed its largest contract to date in the Middle East with a three-year value of almost $500,000 with OQ Oman, a global integrated energy company operating in 17 countries.

5. SmartCap

You have to give a tip of the hat to this team. An active job site or the highway is no place for a nap. SmartCap’s wearable hat technology was developed using electroencephalography as it is unaffected by glare, humidity, head turns, eye disease, or behaviour. SmartCap’s tech is predictive and does not require post processing or live monitoring of data to provide real-time operator alerts. The Australian company has caught the attention of the mining sector. In 2021, SmartCap was acquired by Wenco International Mining Systems, a subsidiary of Hitachi Construction Machinery. This video demonstrates how the product can be used.

6. Boston Dynamics

In addition to progress monitoring, BIM model comparison and digital twin creation, Boston Dynamics’ robots are advancing construction safety. Builders can use the Massachusetts-based company’s Spot robot to survey confined spaces and keep workers out of hazardous environments. They can also feed image data on programmed routes into specialized downstream software to detect health and safety issues. General contractor Pomerleau currently uses Spot to track project progress with HoloBuilder site documentation software.

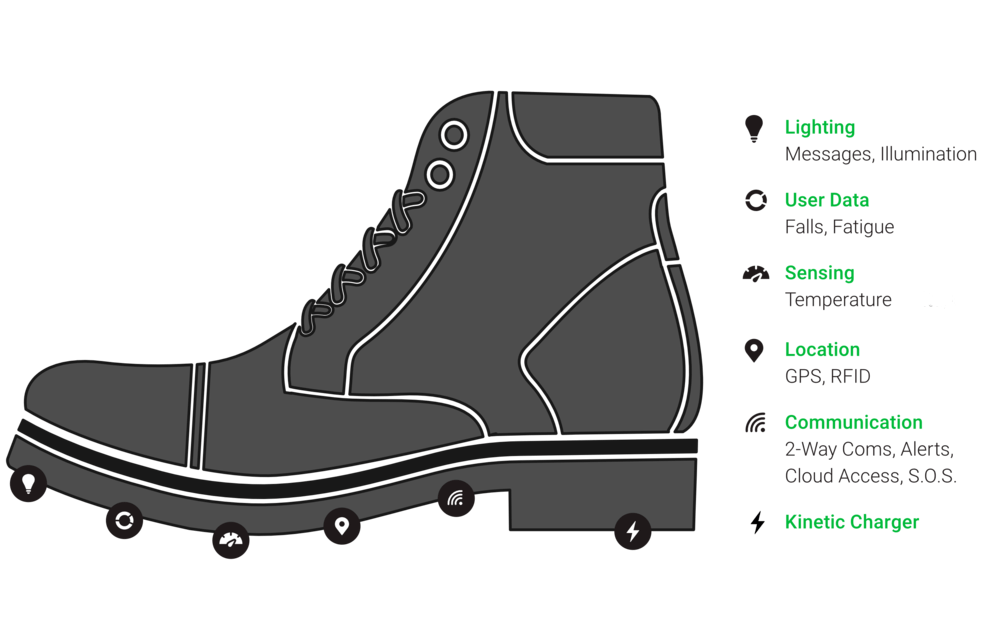

7. SolePower

These boots have a brain. SolePower has developed a proprietary sensor platform that can be installed in standard construction work boots to measure the worker’s indoor and outdoor position, step count, speed, time spent in work areas and more. The data is delivered to a front-end visualization for managers to gain awareness of the workflow and status of their workforce anywhere in the world. The Pennsylvania-based company was founded out of Carnegie Mellon University Engineering and boasts a team of former NASA and manufacturing engineers. They have already successfully delivered test units to the US Army under two consecutive contracts.

8. BC Construction Safety Alliance (BCCSA)

To help builders in B.C. keep workers safe from silica dust exposure, the BCCSA developed the Silica Control Tool. The tool assists employers in conducting appropriate risk assessments and implementing effective controls and safe work practices where respirable crystalline silica dust may be an occupational hazard. The tool relies on scientific studies and data collected from a team of medical researchers. With this it can predict the expected exposures to workers under similar conditions.

9. North American Traffic

Flagging is one of the most dangerous jobs in the industry and every year flaggers are killed by vehicles. But what if a flagger didn’t have to be on the road at all? North American Traffic’s automatic flagging solution has been around for many years but it’s still worth noting. Peter Vieveen, the company’s founder and president developed the device while working in the construction sector and witnessing the dangers flaggers face firsthand.

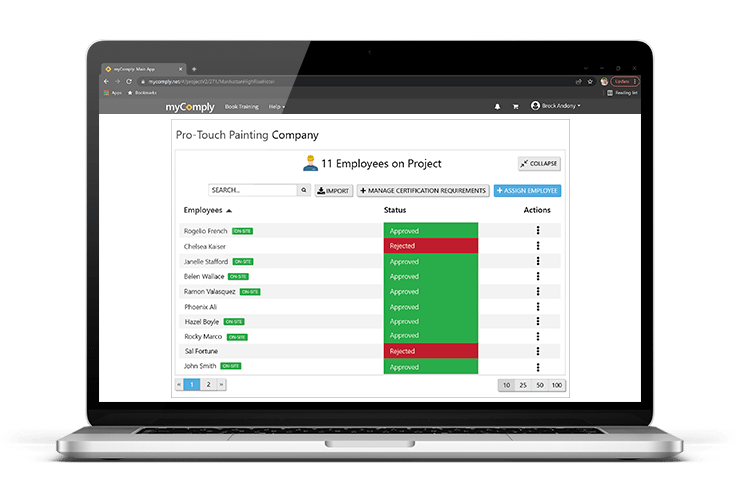

10. myComply

Founded in 2015, Saskatoon and Brooklyn-based myComply is a technology platform that ensures construction site compliance and provides worker analytics. myComply is looking to transform how training certifications are managed and verified on construction sites. The platform combines intelligent hardware with easy-to-use software used to verify safety training. Just last year, the New York City Department of Buildings hired myComply to build and administer the software behind an innovative construction safety database for more than 150,000 workers.

11. Construction Ontario

Construction safety training is beginning to go virtual thanks to training providers like Construction Ontario. Construction Ontario provides ready-to-go, out-of-the-box virtual reality (VR) and interactive e-learning training that uses Microsoft’s Holo Lens 2. Each course is designed with experts in training, and all training modules include active user instruction, reinforcement of OSHA principles, and corrections/tallies of incorrect actions. Construction Ontario noted that studies show VR students learn faster, are more focused and feel more confident than traditional students.

Biolift

Not all construction injuries are sudden and severe. Many creep up on you over time. Montreal-based Biolift wants to give your body a break with its exoskeleton tech. Using compressed air springs, the system stores the mechanical energy of the body when you bend your back and redistributes it when you stand up. By supporting up to 20 kg, the exoskeleton relieves the back to prevent injury and fatigue. Since 2019, the Biolift team has been working with the workers from Eurovia Québec and multiple construction companies to refine the technology.